Faster Rates.

Lower Energy Costs.

Better Mixing.

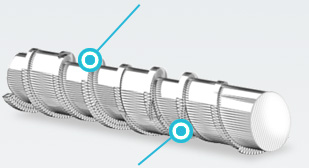

2 sub-channels

Keeps unmelted pellets mixing with fresh melt to yield higher melting ratesundercuts

These flow mechanisms provide uniform melt quality and uniform melt temperature by forcing particles to continuously change their positions.

Superior Productivity

The Barr VBET Mixing Screw is the latest generation of the proven, high performance BARR ET Screw.Patents

USA # 6,599,004AUSTRALIA # 200 225 7190

MEXICO # 240578

Smart.

Efficient.

Economic.

Versatile.

High Level Mixing at Reduced Cost

The Fluxion Mixer is the smart choice of processors in today's economy because it meets the cost reduction demands from global competition and because it provides the ability to perform low shear, high intensity mixing of polymer blends and of multiple polymers in recycling. US PATENT # 5,988,866

dynamic stator

This sleeve fits over the rotor, allowing it to turn in the barrel and rotate at much lower revolutions per minute than the rotor.E.T. Screw

A Landmark in Screw Design

The E.T. (Energy Transfer) Screw was an exciting innovation in extruder screw design which succeeded in maximizing production rates and minimizing wear, while consuming far less energy than other extrusion screws. It is still an exceptional screw by today's standards and was the building block for the even more efficient VBET.US PATENT #4,405,239

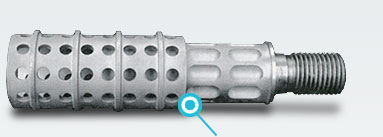

BARR-3 Screw

Still Keepin' It Real

The Barr-3 Screw is a veteran in energy efficiency. It continues to maximize melting with low energy input and high uniform output by controlling the melting process via an innovative channel design.US PATENT #4,000,484